Posted By: ITA-Admin | Date: November 25th, 2014

Electronic components have to be able to withstand the stresses and the variation in conditions that they will be exposed to during their working life. Failure of the component impacts the lifespan of the product. The most common cause of component failure is the solder joint which usually fails because of:

There are techniques available that can test the strength and durability of a solder joint. The three best ways to test the joints are:

There are techniques available that can test the strength and durability of a solder joint. The three best ways to test the joints are:

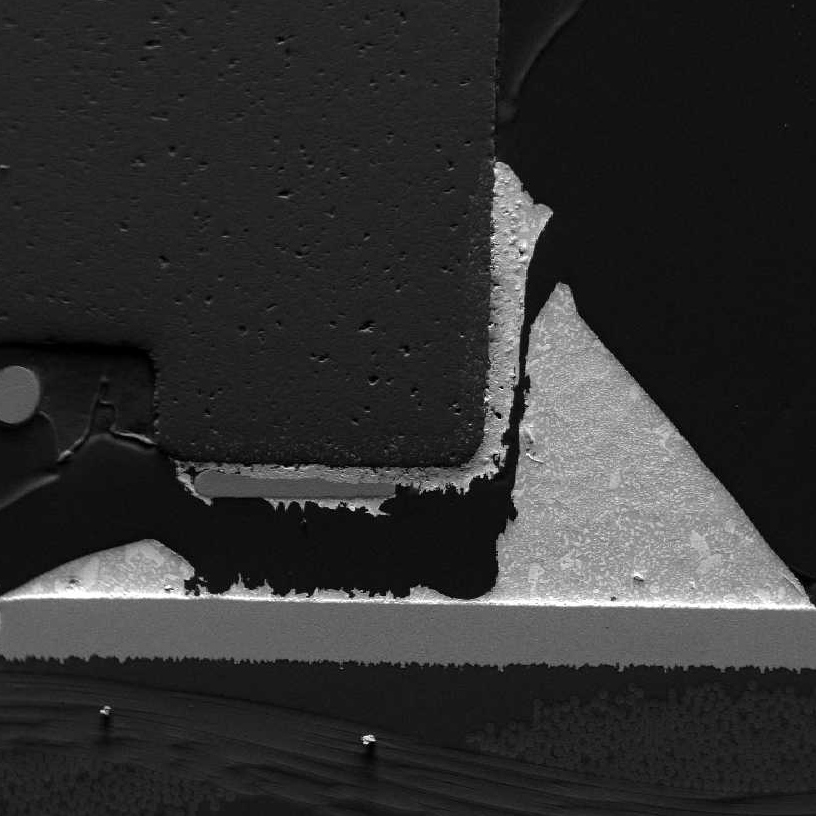

Micro-sectioning

Micro-sectioning (also known as cross-sectioning or metallographic preparation) is the most common technique used. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint and PCB. This process requires the skill of a metallurgist to produce the micro-section and analyse the results for you.

Environmental Temperature Cycling

Commonly known as temperature cycling, this process reproduces the fluctuations in temperature, humidity or vibrations, which a product is exposed to. The environmental testing chamber simulates the temperature range that a PCB might experience during its lifespan. Temperature cycling could be a range from -55°C to +125°C and over 500, 100 or 2000 cycles. The range of temperature and the number of cycles depends upon the usage of the component in the final product.

Doing sheer testing as part of the environmental test program can speed up this process as it gives an early indication of which solder joints or alloys will fail.

Drop Testing

This technique involves repeatedly dropping the PCB from various altitudes to test the strength of the solder joint. It is inevitable that the solder joint will eventually weaken but it identifies the number of drop cycles and therefore the potential lifespan of the solder joint.

The most common technique used is temperature cycling over a specific range. There are IPC standards, which define what to do and how to do it, but you need a laboratory with the right equipment to be able to do these assessments for you accurately, quickly and safely.

For more information on Component Failure Analysis please visit

https://www.italabs.co.uk/services/electronics-failure-analysis-testing-services/