Microsectioning, also known as Cross-sectioning or Metallographic Preparation, is the art of taking a two dimensional slice out of a sample in order to uncover an important feature.

Microsectioning, also known as Cross-sectioning or Metallographic Preparation, is the art of taking a two dimensional slice out of a sample in order to uncover an important feature.

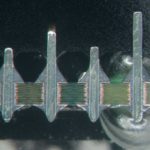

The microsectioning technique can be used for a variety of applications, for example revealing coating layer uniformity and thickness in plating finishes, or ascertaining the nature of the interface between the solder and Printed Circuit Board (PCB).

The process of microsectioning is multi-stage and starts with the isolation of the area of interest from the rest of the assembly. This could involve delicately cutting an area around an electronic component from a PCB.

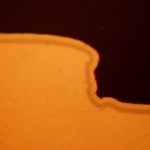

Once isolated, the component is then encapsulated into a potting medium (e.g., epoxy resin) within a mould and is left to cure.

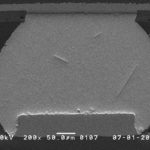

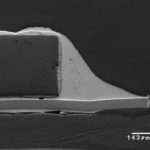

On solidification, the mounted sample, or microsection, is retrieved from the mould and the sample face is gradually receded back using a series of abrasive material.

Once the features is revealed by this cross-sectioning, the microsection face is subjected to a number of polishing stages to generate a highly reflective finish that is then ready for optical and/or electron microscopy analysis to check such things as the plating thickness, coating thickness or failures in the solder joint.

|

|

|

|

The key pieces of kit in the microsectioning process, namely the encapsulating materials, grinding wheel and automated polishing system, are all supplied by Struers. ITA Labs’ UK laboratory is extremely experienced at providing sample analysis test results, with a fast turnaround, at very competitive rates.

To discuss your potential requirements, call Alastair on 01727 871301.

+44 (0) 1727 871301